Eye Drops Filling Production Line

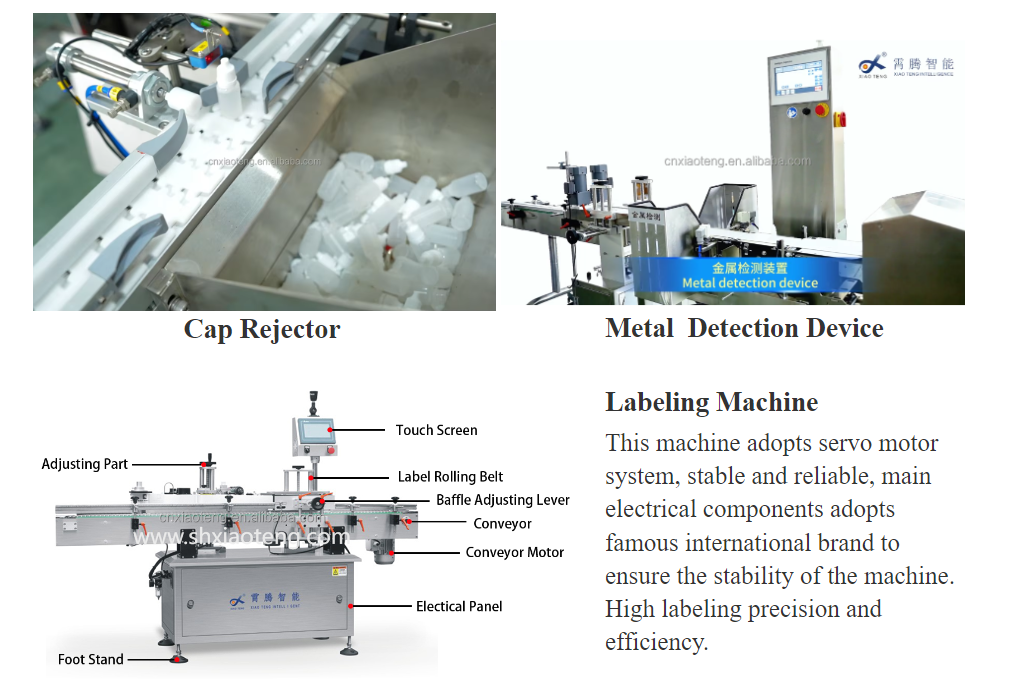

The Eye drops filling production line is composed of five types of equipment: Bottle unscrambler, Liquid filling plugging and capping machine,Cap Rejector,

Metal Detection Device and Labeling Machine.

| Product Name | Bottle Unscrambler |

| Labeling Speed | 10-120 bottles/min(Related to bottle and label size) |

| Labeling Accuray | ±1mm |

| Material Size | Φ40-φ 90mm (H) 40-100mm |

| Machine Size | 1200*1150*1300mm |

| Weight | 380KG |

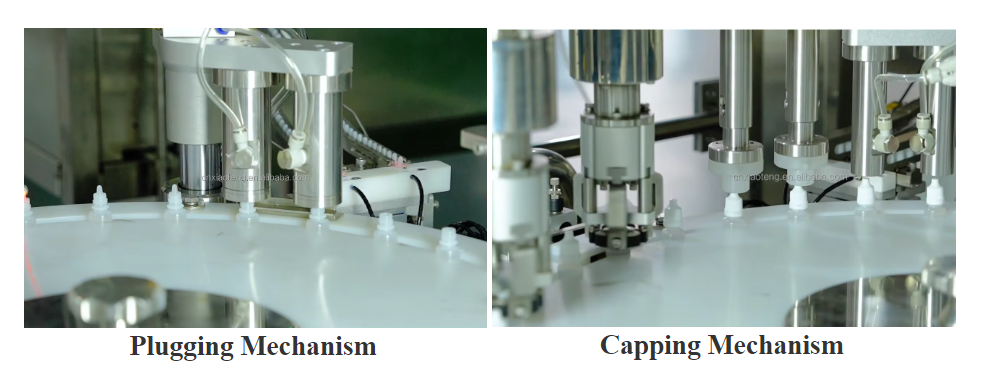

Filling And Capping Device

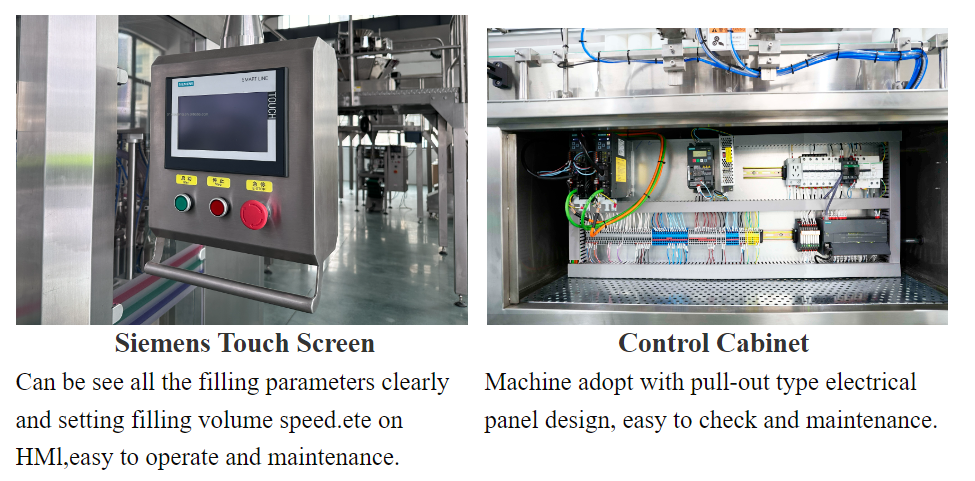

Automatic filling, plugging &capping machine for the application of round /flat small bottle or similar ones, auto accomplish product filling, plug place, cap place, cap screw-on. The machine is composed by a conveyor,fill nozzles, plug &cap sorter, Plug &cap placer, cap screw-on system.

| Product Name | Automatic Filling Capping Machine | ||

| Filling Speed | 50-80b/m50-80b/m | ||

| Bottle Size | Min. Ø 20mm Max. Ø30mm | ||

| Filling Volume | 5-50ml | ||

| Filling Accuracy |

±1

|

||

| Power Supply | 3 Phase, 380V, 50Hz | ||

| Power | 1500W | ||

| Compress air require | 100L/min, 4~6bar | ||

| Machine Size | 2500*1800*1950mm | ||

| Weight | 1400KG | ||

| Product Name | Automatic Labeling Machine |

| Labeling Speed | 10-150 bottles/min(Related to bottle and label size) |

| Labeling Accuracy | ±1mm |

| Suitable bottle Diameter | (L)20-280(W)30-140mm |

| Material Size | L)25-85mm(H)40-120mm |

| Label Roll Inside Diameter | 76mm |

| Label Max Outside Diameter | 350mm |

| Output Power | 1500W |

| Machine Size | 2000*850*1600mm |

| Weight | 250KG |

-封面.jpg?x-oss-process=image/resize,w_100/quality,q_100)