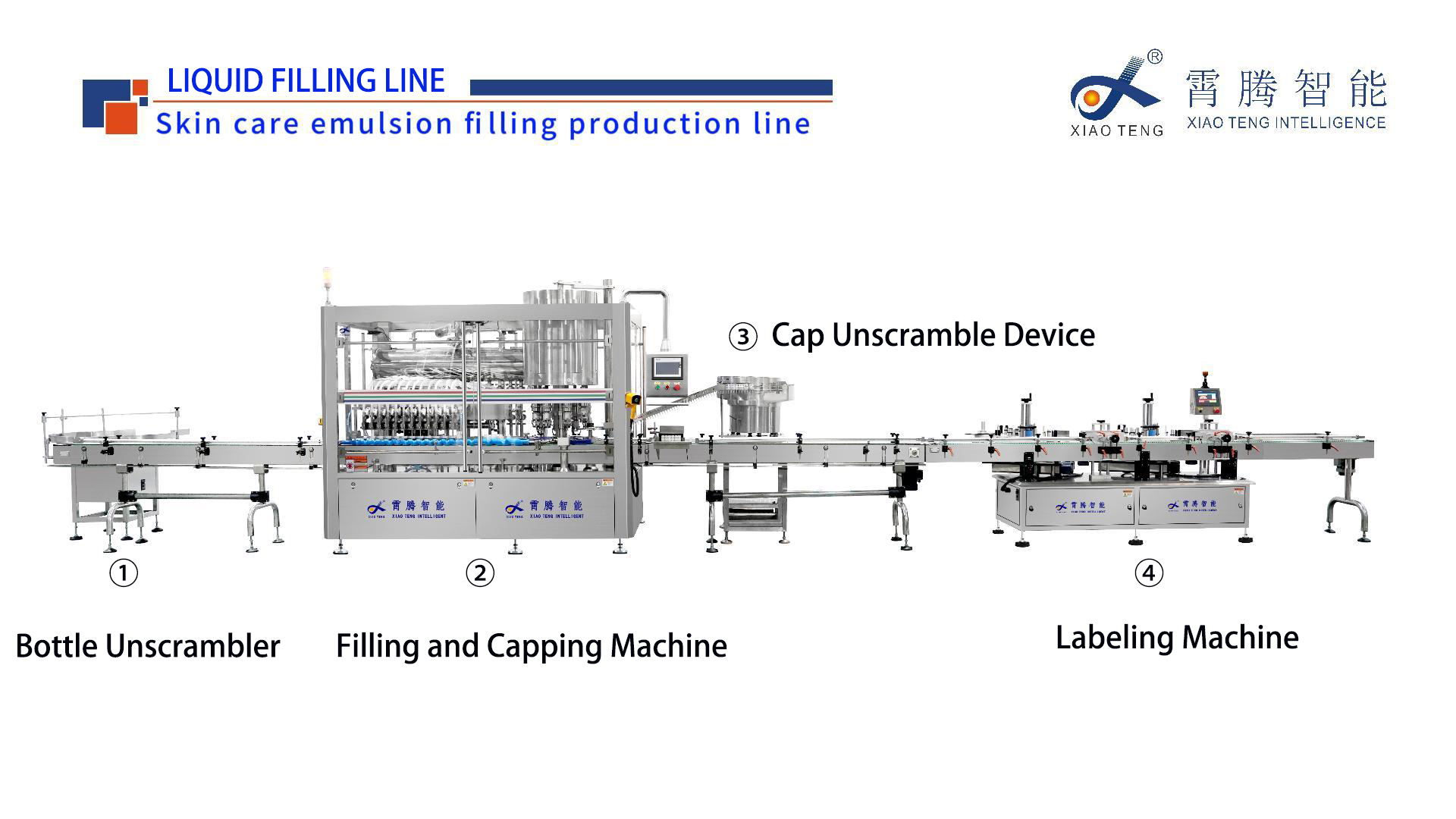

Skin care emulsion filling production line

Our state-of-the-art emulsion filling production line is engineered to meet the rigorous demands of modern skincare manufacturing. Combining cutting-edge automation, sterile processes, and customizable flexibility, this system ensures seamless, high-speed filling of emulsions while adhering to global quality standards.

Key Features:

✅ Fully Automated Operation – Minimize human intervention with robotic arm integration for precise bottle handling, filling, capping, and labeling.

✅ Aseptic Filling Technology – ISO-certified cleanroom compatibility and anti-contamination design to preserve emulsion integrity.

✅ High-Precision Metering – ±1% accuracy for consistent fill volumes across viscosities (5–50,000 cP).

✅ Versatile Packaging Adaptability – Quick-change tooling supports tubes, bottles, jars, and airless pumps (10ml–500ml).

✅ Smart Quality Control – AI-powered vision inspection for leaks, cap alignment, and label accuracy.

✅ Energy-Efficient Design – Reduced waste and 30% lower energy consumption vs. conventional systems.

✅ GMP/ISO Compliance – Full traceability with data logging for batch records and regulatory audits.

-封面.jpg?x-oss-process=image/resize,w_100/quality,q_100)