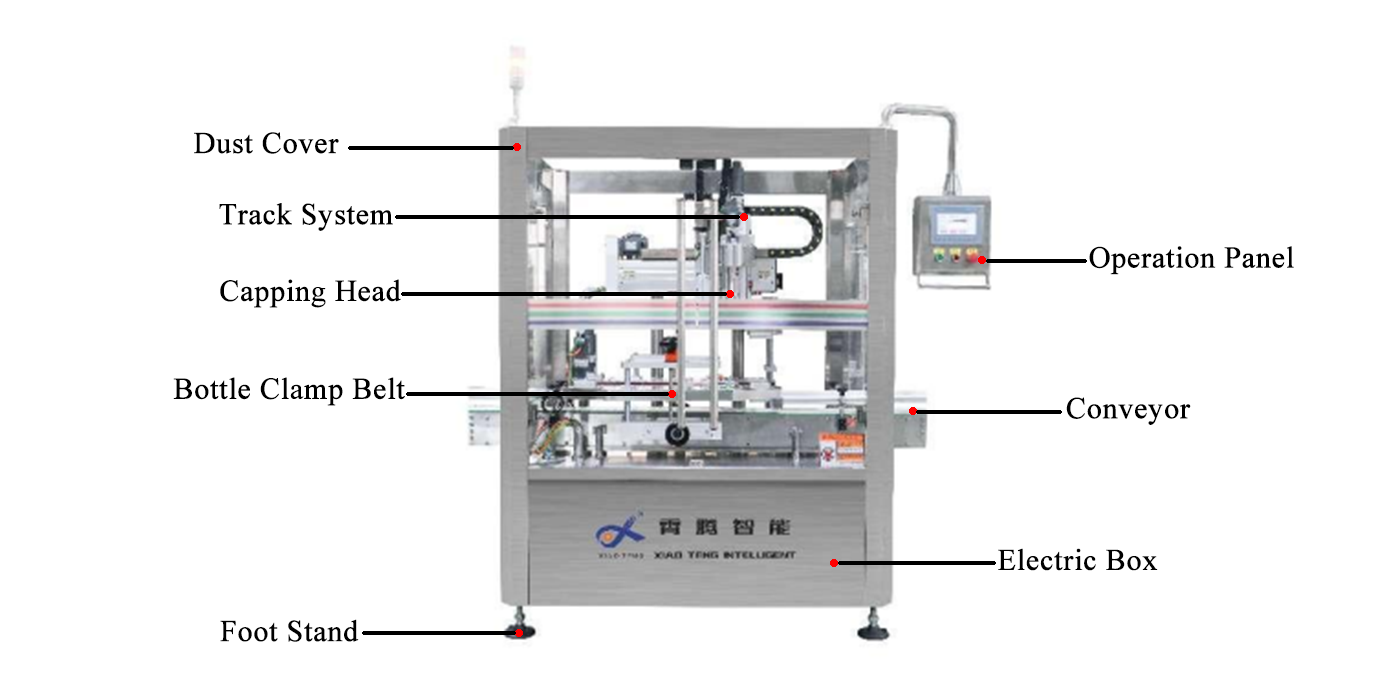

Automatic Tracking Capping Machine

Brief Introduction

XT-RTA-1 full-automatic cap-screwing machine adopts vibrating cap-arranging and draw-to-take cap-feeding design. Caps will be nested into cap-screwing head firstly and then screwed onto containers, ensuring qualified rate. It is applicable to plastic threaded caps, aluminium caps and press-in caps with replacing different cap screwing mechanism.

Design of this machine has features of flexible replaceability and simple operation, which is easy to replace different containers. It can be used independently or matched to production line. General chemical industry, medicine, food, cosmetic, cleaning supplies, etc. is applicable.

Main parameters:

|

Applicable bottle size |

L:50-150mm W:50-150mm H:60-250mm |

|

Bottle cap specifications |

Φ25-50mm |

|

Production capacity |

20-30bpm |

|

Air source pressure |

0.5~0.7 MPa |

|

Power supply |

220V、50/60HZ |

|

Output power |

3KW |

|

Weight |

600kg(About ) |

|

Boundary size |

2100×1500×2000mm |

Configuration:

|

No |

Product Name |

Material |

Brand |

Origin |

|

1 |

Machine |

SUS304 |

|

|

|

2 |

Protective Cover |

PC |

|

Optional |

|

3 |

PLC |

|

Siemens |

Germany |

|

4 |

HIM |

|

Siemens |

|

|

5 |

Transducer |

|

Siemens |

Germany |

|

6 |

Pneumatic Components |

|

Airtac |

Taiwan |

|

7 |

Servo system |

|

Siemens |

Germany |

|

8 |

AC motor |

|

JSCC |

Germany |

|

9 |

Electric Elements |

|

Schneider |

Germany |

|

10 |

Direct-Current Main |

|

Delta |

Taiwan |

|

11 |

Photoelectric Sensor |

|

Leuze |

Germany |