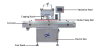

Automatic Linear Fixed Capping Machine

Performance Features

The tunnel has photoelectric sensor device, to control the elevate of the cap.

When the cap is full on the tunnel, it will automatic stop delivering the cap.

Digital display the capping degree for your reference.

Adopts PLC control, stepless adjustment.

The capping area has organic glass protection cover, which can protect the safety of the operator.

The surface of the machine adopts SS AISI 304, fully meet the GMP requirement.

XT-CGJ fixed type screw capping machine adopts advanced technology, high grade stainless steel, compact structure, beautiful outlook, convenient maintenance, widely used in daily products, pharmaceutical, health care products, food industry, etc. Applicable to various kinds of containers(round bottle, flat bottle, square bottle)cap loading and capping. The bottle which already after filling are conveyed by conveyor and bottle separating wheel to the capping position, the cap is elevated from the hopper to cap loading tunnel(the reverse cap will be rejected),the cap will be dropped from the tunnel and then load on the bottle mouth; then, the container will go into the grasp bottle mechanism, the bottle body will be fixed tightly by two belts, at the same time, the three capping wheel of the cap screwing mechanism will screw the cap for three times, the after capping bottle will separate from the belt and then conveyed to next procedure.

| Air consumption | 300L/min |

| Speed | 20-40bottles/min |

| Voltage | 220V 50Hz |

| Suitable Cap Size | Ø15~Ø 70 |

| Total power | 1.25KW |

| Bottle body diameter | Ø20~Ø100mm |

| Overall dimension | 2430*900*2141mm |

| Bottle height | 80-240mm |

| Conveyor height | 970+/-50mm |

| Weight | 750Kg |