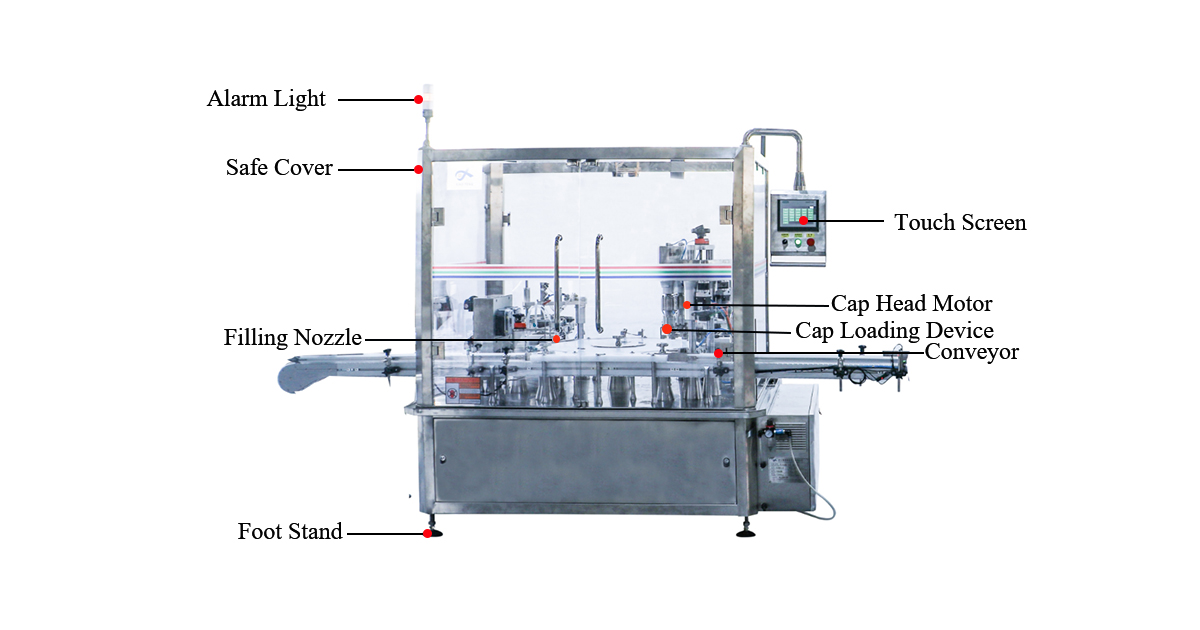

Automatic Filling Oral Liquid Plugging And Capping Machine

General Features:

Automatic filling, plugging &capping machine for the application of round /flat small bottle or similar ones, auto accomplish product filling, plug place, cap place, cap screw-on. The machine is composed by a conveyor, peristaltic pump &fill nozzles, plug &cap sorter, Plug &cap placer, cap screw-on system. The bottle loading/unloading is done manually, through loading/unloading turntable Ø620mm, or directly from an production line. It is designed and made accordance to GMP regulation.

|

Kind of bottle |

Various kind, e.g. round, flat, oval |

|

Bottle size* |

Min. Ø 20mm Max. Ø30mm |

|

Speed |

20~30bpm |

|

Filling volume* |

5-50ml |

|

Filling accuracy |

±0.1ml@5ml |

|

Power* |

220V 50/60Hz 1.5kw |

|

Compress air require |

100L/min, 4~6bar |

|

Machine size mm |

Length 2500, width 1800, height 1950 |

|

Machine weight: |

1400kg |

* Other sizes on request

Function and Technical Standard:

|

S/N |

ITEM |

DESCRIPTION |

|

|

Conveyor |

|

|

|

peristaltic pump Pump* |

|

|

|

Plug &cap sorter |

|

|

|

Plug &cap placer |

|

|

|

Screw-on capper |

|

|

|

PLC controller |

|

|

|

Machine frame |

|

|

|

Accessories |

+Silicone tube Φ10X2 4m +capper rubber 30x30cmx1unit |

Configuration list:

|

No. |

Item |

Model |

Origin |

Quantity |

|

1 |

Peristaltic Pump |

25ml |

China |

2 |

|

2 |

Capping motor |

5IK90GN-CF |

Servo motor Siemens |

1 |

|

3 |

Conveyor motor |

6IK140RGN-CF |

Servo motor Siemens |

1 |

|

4 |

PLC |

TM218LDA16DRN |

Siemens |

1 |

|

5 |

Touch Screen |

HMIGX03501 |

Siemens |

1 |

|

6 |

Inverter |

ATV12HU15M2 |

French Schneider |

1 |

|

7 |

Optical fiber sensor |

BF3RX-FD-620-10 |

keyence |

2 |

|

8 |

Proximity Switch |

IBT18-S05NA-D3Y2 |

AirTAC |

6 |

|

9 |

Contactor |

LC1-D0910 |

French Schneider |

1 |

|

10 |

Relay |

NY4NJ |

Japan Omron |

4 |

|

11 |

Air switch |

OSMC32N1C10 |

French Schneider |

2 |

|

12 |

SMPS |

S-50-24 |

Taiwan MW |

1 |

|

13 |

Main motor |

YVF2-80M2-4 0.75kw |

Shanghai DEDONG |

1 |

|

14 |

Other Pneumatic elements |

|

Taiwan Airtac |

10 |